How Does a Twin-Screw Extruder Work? -3

7. Homogenization and Controlled Molding Stage

Working component: mold

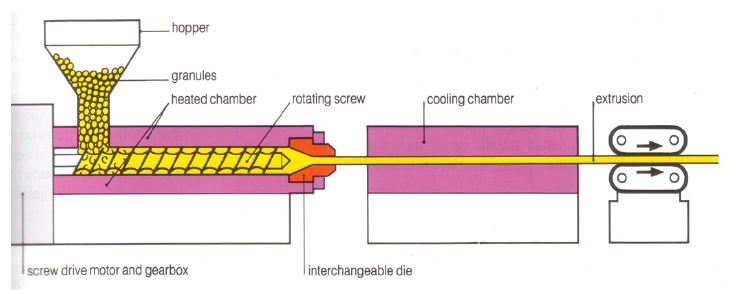

The homogenized melt is pushed to the mold by the extruder and molded into the desired shape, such as sheet, tube or film through the mold. The mold design depends on the shape and specifications of the final product.

8. Cooling and Solidification Stage

Working component: water bath, cooling fan

The extruded product is quickly cooled and solidified by the cooling system to maintain its shape and dimensional stability. Cooling methods include water bath cooling, air cooling, etc.

9. Cutting and Post-processing Stage

After the cooling stage, the solidified plastic can be further processed, especially in plastic modification applications. At this stage, precision becomes critical. The solidified plastic goes through a cutting process, usually done by specialized equipment such as a granulator, to ensure that the resulting pieces or pellets are uniform in size. The choice of cutting into small pieces or pellets depends on the specific requirements of the application. The processed material is then collected and used in downstream manufacturing processes.

Conclusion

Twin-screw extruders are widely used in plastic processing and modification. Their excellent mixing, melting and reaction capabilities enable them to process various types of plastics and give them new properties, and improve the comprehensive performance of materials. Plastic pellets made by twin-screw extruders can meet the needs of different application fields.

NOVISTA has long been engaged in the development and sales of additives products in the PVC industry, as well as market promotion. We can provide customers with a full set of PVC products solutions, from the start-up of the testing machine to production formula adjustment, as well as production performance improvement suggestions, we will continue to provide customers with the best quality service.

If you have any requirements of PVC impact modifier, Acrylic processing aids and PVC stabilizers, please feel free to contact us.

(THE END)