The causes and solutions of abnormal phenomena in PVC pipes processing

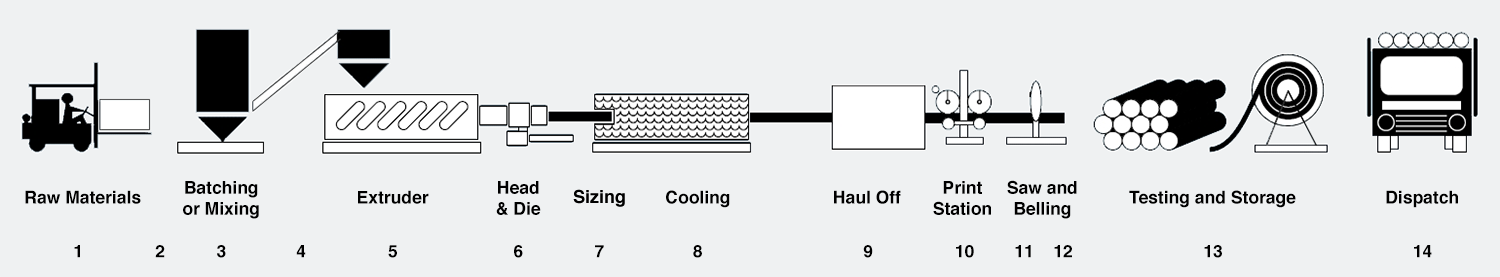

(Manufacturing process of PVC pipe)

The following are the causes and corresponding solutions of abnormal phenomena that are likely to occur during the processing of PVC pipes.

1. Corrugations on the outer surface of PVC pipes

Causes | Solutions |

1. Uneven overflow around the die of PVC pipe extruder 2. High cooling water temperature 3. small and uneven water spray volume of the sizing sleeve 4. Unstable speed of PVC pipe extruder | 1. Check the die electric heating ring 2. Decrease water temperature or increase the volume of cooling water 3. Increase the amount of water spray and clean the water spray heads around the sizing sleeve. 4. Adjust the pulling speed of PVC pipe extruder |

2. Cracks in the inner wall of PVC pipes

Causes | Solutions |

1. There are impurities in the material 2. The temperature of the front part of the machine or the machine head is too low 3. The core mold temperature is too low 4. Towing speed is too fast 5. Inappropriate amount of lubricant in the formula | 1. Replace raw materials 2. Increase processing temperature 3. Increase core mold temperature 4. Reduce towing speed 5. Adjust the formula or adjust the ingredients |

3. Lumps and bulges (like bubbles) on the inner or outer walls of PVC pipes

Causes | Solutions |

1. Too much water in the material 2. There are impurities mixed in the material or the remaining material added is not removed 3. The extruding temperature is too low 4. The temperature of the conveying section is too high, which is not conducive to the vacuum moisture removal | 1. The raw materials are fully dry 2. Remove impurities. When reusing the remaining materials, be sure to remove the decomposed materials and impurities. 3. Increase the extruding temperature. 4. Reduce the temperature of the conveyor section |

4. Burnt particles or dividing lines appear on the PVC pipe wall

Causes | Solutions |

1. The filter plate is not cleaned 2. The temperature control instrument fails, and the temperature of the extruder and head is too high. 3. There are dead corners or scratches in the machine head 4. The screw is worn or there is decomposed material in the screw 5. The design of the machine head splitter is unreasonable and there are blind spots. 6. The inner surface of the PVC pipe extruder head is rough and the material is stuck. 7. The manufacturing cycle is too long and the material stays in the barrel for too long. | 1. Stop the machine and clean the filter plate again 2. Lower the temperature, inspect the instrument, and verify with a mercury thermometer. 3. Stop the machine to clean the machine head and polish it with a polishing wheel. 4. Inspect and polish the screw 5. Improve the head structure of PVC pipe extruder 6. Stop the machine and polish the inner surface of the machine head 7. Increase extrusion speed or adjust formula |

As a professional solution provider of PVC processing technology, NOVISTA provide the high quality PVC additives, including PVC impact modifiers (CPE/Acrylic impact modifiers/MBS), processing aids (Acrylic polymers/lubricants) and PVC stabilizers (Ca-Zn stabilizers/One-pack metal stabilizers).

And we are also looking for professional distributors/agents for the promotion of PVC additives & CPVC in Global market...

Please feel free to contact us.