Why is Calcium Stearate So Significant in PVC? -1

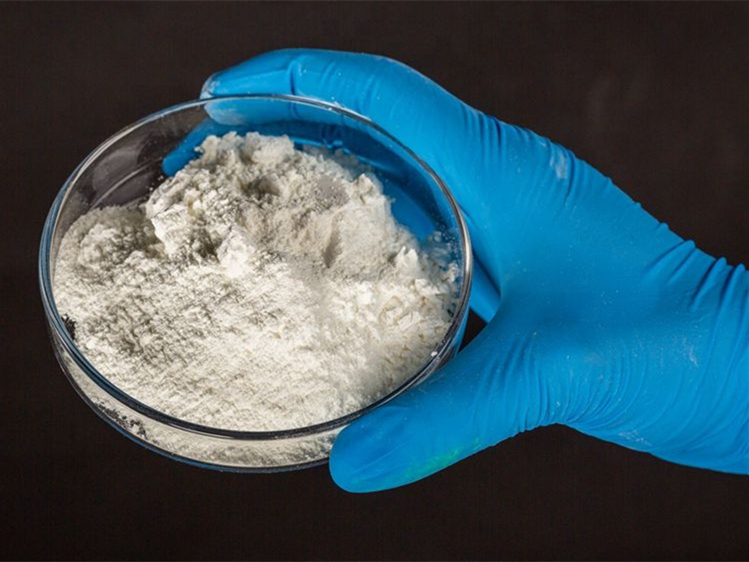

Calcium stearate is a white waxy powder referred to as calcium soap. It remains insoluble in most solvents and is biologically safe to use. Unlike wax, it does not get greasy even at increased temperatures because of its comparatively higher softening point.

Calcium stearate has numerous uses across several industries. Besides being used as an anti-caking additive in cosmetics and pharmaceuticals, it serves as a waterproofing additive in construction. If we talk about calcium stearate uses in PVC, it serves as a lubricant and release agent in the plastics industry. Moreover, it is tremendously used as an acid scavenger.

The common characteristics of Calcium Stearate PVC Stabilizers are as follows:

Color: White

Form: Non-dusting Fine Powder

Bulk Density (g/cc): 2-0.3

Melting range: 140 -155°C

Moisture content: 0 % Max

Free fatty acid: 0 % Max.

Ash content: 5 – 11 %

Particle passing through 200 mesh: 99 % min