How will internal and external lubricants determine product quality in PVC-U processing?

Have you ever encountered problems such as rough surfaces of PVC pipes, frequent jamming during extrusion? or oil spots on food-grade PVC packaging films and substandard mechanical properties? 80% of these seemingly unsolvable production problems are rooted in the balance of the lubrication system.

I. Core Functions of Internal Lubricants

1. Reducing friction between resin molecules and promoting plasticization

Internal lubricants (such as stearic acid, glyceryl stearate, etc.) have good compatibility with PVC resin. They can insert between resin molecular chains, weaken the van der Waals forces between molecules, and reduce melt viscosity.

- Principle analysis: During the plasticization stage, internal lubricants can reduce the frictional heat inside resin particles, lower the plasticization temperature, shorten the plasticization time, and avoid resin decomposition caused by frictional overheating. For example, insufficient internal lubrication will increase the plasticization torque of the resin, leading to problems such as yellowing of products and decreased mechanical properties.

2. Improving melt fluidity and uniformity

Internal lubricants reduce the entanglement between molecular chains, making the melt flow more easily during extrusion or injection molding, while promoting the uniform dispersion of fillers and additives.

- Typical scenario: In pipe extrusion, sufficient internal lubrication can avoid wall thickness deviation caused by uneven melt flow, or "bamboo joint patterns" caused by poor local plasticization.

II. Core Functions of External Lubricants

1. Reducing friction between the melt and equipment surfaces

External lubricants have poor compatibility with PVC resin and tend to migrate to the interface between the melt and equipment (such as screws, molds), forming a lubricating film and reducing adhesion.

- Key role: Prevent the melt from adhering to the screw or die, avoid scorching caused by local overheating, and reduce equipment wear. For example, external lubricants such as zinc stearate and paraffin can significantly improve the release property of the melt, especially in profile extrusion, which can reduce scratches and roughness on the product surface.

2. Regulating plasticization rate to avoid over-plasticization

External lubricants form an isolation layer on the surface of resin particles in the early stage of processing, delaying the melting rate of the resin and thus controlling the overall plasticization rhythm.

- Balance logic: Insufficient external lubrication may cause peroxide decomposition due to too fast plasticization, resulting in bubbles; excessive external lubrication will prolong the plasticization time and even lead to "oil exudation" (lubricant precipitation) on the product surface.

III. Synergistic Mechanism of Internal and External Lubricants

1. Core logic of lubrication balance

- Internal lubrication dominates plasticization efficiency: Ensure the resin is fully melted at a reasonable temperature, avoiding thermal degradation caused by excessive molecular friction.

- External lubrication dominates processing stability: Control the interfacial friction between the melt and equipment, prevent adhesion and overheating, and assist in regulating the plasticization rate.

2. Consequences of imbalance

- Insufficient internal lubrication + excessive external lubrication: Prolonged plasticization time, decreased mechanical properties of products, and easy oil exudation on the surface.

- Excessive internal lubrication + insufficient external lubrication: The melt adheres to the equipment, prone to scorching, and the product surface is rough.

3. Impact of process parameters on lubrication balance

- Temperature fluctuations: High temperature will accelerate the volatilization of external lubricants (such as paraffin), breaking the balance; low temperature may weaken the effect of internal lubrication and increase melt viscosity.

- Screw speed: High speed will increase shear force. At this time, it is necessary to appropriately increase external lubrication to reduce friction between the melt and the screw, while avoiding overheating caused by insufficient internal lubrication.

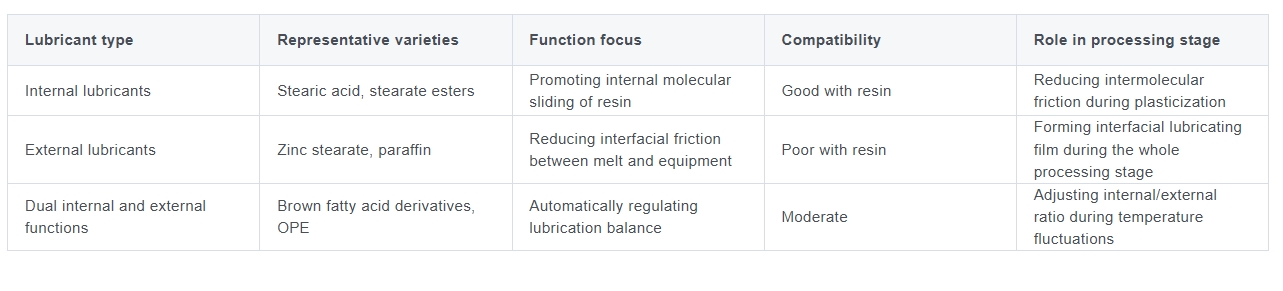

IV. Comparison of Performance Characteristics of Typical Lubricants

V. Balancing Strategies in Practical Applications

1. Adjusting the ratio according to product type:

- Rigid pipes (e.g., water supply pipes): Higher internal lubrication is required to ensure uniform plasticization, and an appropriate amount of external lubrication to prevent mold sticking.

- Transparent sheets: Avoid exudation of external lubricants, focusing on internal lubrication (e.g., selecting ester lubricants).

2. Optimizing in combination with process conditions:

- High-temperature processing (e.g., high-speed extrusion): Use low-volatility external lubricants (such as PE wax) to reduce balance damage caused by volatilization.

- Low-temperature processing: Increase the proportion of internal lubrication to make up for plasticization difficulties caused by insufficient temperature.

Summary

In the PVC-U lubrication system, internal and external lubricants complement each other by "regulating intermolecular friction" and "controlling interfacial lubrication". Their balance directly affects plasticization quality, processing stability, and product performance. In actual production, it is necessary to reasonably select lubricant types and ratios according to resin characteristics, process parameters, and product requirements. Meanwhile, volatile components should be avoided, and self-regulating lubricants (such as OPE) should be introduced when necessary to enhance the system's adaptability to process fluctuations.