THE K VALUE OF PVC RESIN-2

Characteristics of different K values:

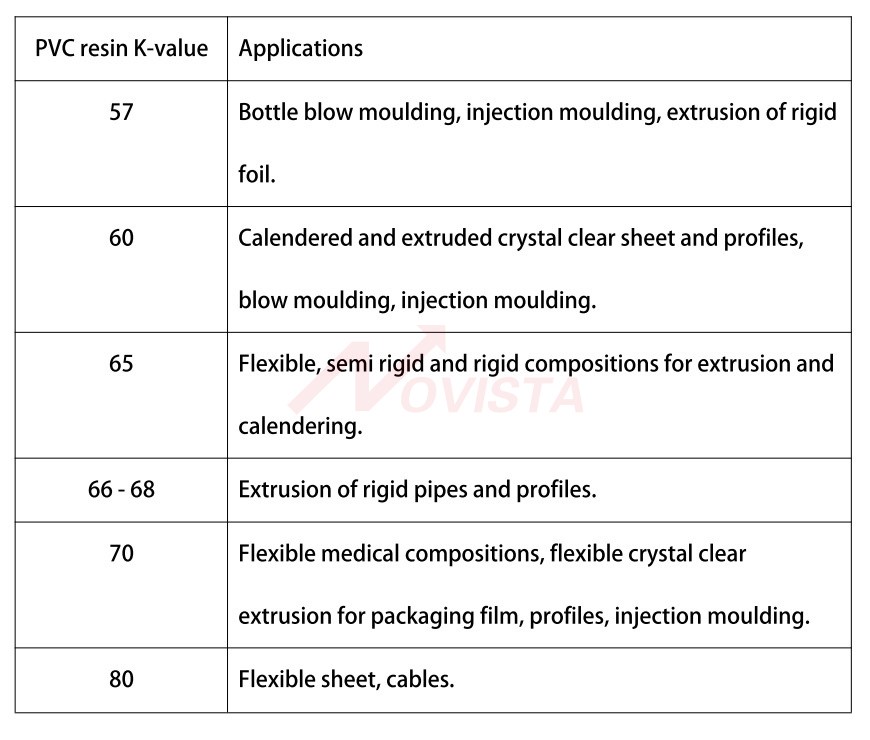

• K70-75 are high K value resins which gives best mechanical properties but are more difficult to process. They need more plasticizer for same softness. High performance Cable insulations in Suspension resin and tough coatings for Conveyor belts, Industrial Flooring and similar high-end applications in Paste grade are some popular applications. It is the costliest.

They are widely used in the production of PVC soft products, such as soft hoses, wires & cables, shrinkage films, shoes, toys, auto spare parts…and so on…

• K65-68 are medium K value resin which are the most popular. They have a good balance of Mechanical properties and processibility. UPVC (Unplasticized or Rigid PVC) is made from the less porous grades while Plasticised Applications are best made from the more porous grades. There is a lot of grade choice as they cater to the Majority of PVC applications. Because of its sheer volume this family of PVC resins are priced the lowest.

Most of them can be used in the construction materials, such as UPVC pipes, profiles, boards…

• K58-60 are low K-value ranges. Mechanical properties are lowest, but processing is easiest. Many difficult to process applications like injection molding, blow molding and Clear Calendered packaging film are made from the lower K value ranges. Prices are higher than Medium K Value Resins.

They can be made into PVC fittings, sheets, PVC containers…

• K50-55 are special resins which are tailor made for some demanding applications. Interesting ones are Battery Separator Resins and Blending resins used along with Paste Grade resin to reduce costs. Processing is easiest.