Common faults and solutions of plastic pipe extrusion line-1

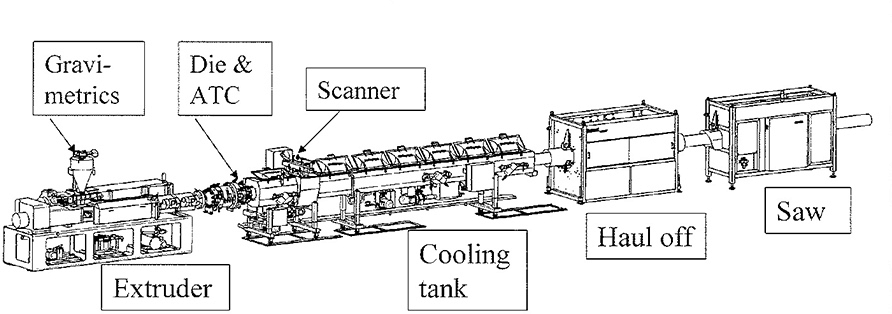

During the production line of plastic pipes, due to various reasons such as the operator's unskilled craftsmanship and machine operation, the plastic pipes often appear rough on the outer surface, jitter rings appear inside, uneven wall thickness, and insufficient roundness. Therefore, it is necessary to adjust the process in time and eliminate the failure of the plastic pipe extrusion line to improve product quality.

1. Rough outer surface of plastic pipe

Adjust the process temperature; reduce the cooling water temperature, the best cooling water temperature of the PE pipe is 20~25℃; check the water circuit for blockage or insufficient water pressure; check whether the heating ring of the barrel, head, etc. is damaged; adjust the sizing sleeve to enter Water flow; check the performance and batch number of the raw materials; check the temperature of the core of the mold, if it is higher than the temperature of the die section, lower the temperature of the core; clean the aggregate of the mold;

2. Grooves appear on the outer surface of the plastic pipe

Adjust the water outlet pressure of the sizing sleeve, and the water output is required to be balanced; adjust the nozzle angle in the vacuum sizing box to make the pipe cool evenly; check whether there are debris, burrs, etc. on the die, sizing sleeve, cutting machine and other hardware;

3. Grooves appear on the inner surface

Check whether water enters the inner tube. If water enters, pinch the tube embryo of the mold just after the exit to seal the inner cavity; reduce the internal temperature of the mold; clean and polish the mold;

(To be continued...)