Topadd® Impact Modifier

We offer an extensive range impact modifiers (Acrylic/CRA/MBS impact modifier), product overview as following:

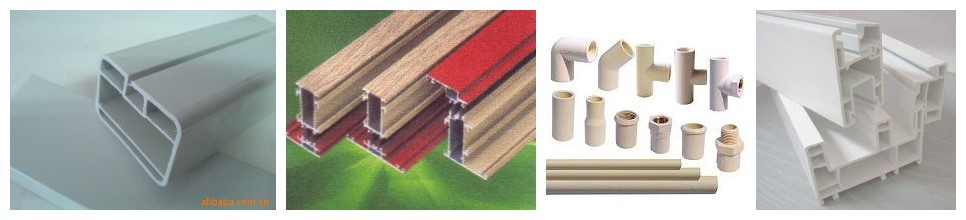

Topadd®AIM: Acrylic impact modifier with core - shell structure in which core being moderate cross linked structure is linked with shell by grafting copolymerization. It is especially suitable for outdoor products and broadly used in PVC profiles, sheets, boards, pipes, pipe fittings, etc

Acrylic Impact Modifier (AIM) Grades List:

TIM808A

Topadd® CRA is our unique PVC impact modifier developed by our R&D Center, which is an interpenetrating network copolymer (IPN),Its main function is to enhance the impact strength of PVC finished products under low temperature and to promote the fusion property of PVC blend. It can endow the best impact-resistance and toughness to PVC final products than other PVC impact modifiers.

In addition CRA series have better weatherability owing to it has not any chemical double bond. CRA series are insoluble in water and ethanol, but soluble in acetone and chlorofor.

CRA Impact Modifier Grades list:

(1)CRA-01M: replace opaque MBS

(2)CRA-02A: replace AIM (acrylic impact modifier)

(3)CRA-03CA: replace CPE+AIM (acrylic impact modifier) with less dosage

(4)CRA-04CP: replace CPE+PA (processing aid) or 100% CPE with less dosage

Topadd® MBS: MBS products developed with advanced synthetic resin technology, ternary copolymerized by Methyl Methacrylate(M), Butadiene(B) and Styrene(S). It is an integrated resin for improving impact strength and processing performance of PVC products. It is widely used in indoor products such as PVC films, sheets, pipes, pipe fittings and granular bottle materials.

MBS Impact Modifier Grades List:

MIP-0701: Opaque grades: Costly and high impact efficiency

MIP-0702: Opaque grade: Excellent improved impact efficiency

MIP-T801: Transparent grade: outstanding crease-whitening and excellent transparency

MIP-T802: Transparent grade: excellent impact strength and good transparency

MIP-T803: Transparent grade: for general purpose,balance performance

MIP-606: Impact Modifier for PolyCarbonate (PC)

ABS, which stands for Acrylonitrile Butadiene Styrene, is currently the world's most produced and widely used polymer. It is a thermoplastic material utilized across multiple industries due to its remarkable properties.

With its toughness, impact-resistance, and lightness, ABS plastic is easy to machine, mold, and fabricate. Its high strength, rigidity, dimensional stability, and resistance to chemicals, heat, and abrasion make it an ideal material for various applications, such as automotive parts, toys, household appliances, pipes, and fittings.

Topadd® HI861/HI961 as a highly effective ABS impact modifier, is in white powder or particle form, can be insoluble in water and ethanol, soluble in trichloromethane, butanone, etc. The content of rubber is 60~65%.

It can be used as the impact modifier to toughen ABS, PC/ABS, PVC, etc., and can also be used to produce ABS resin by mixing SAN resin.

When producing general-purpose ABS, only 23-28% of this product needs to be added to achieve the required performance.

Application uses: